Oldham Simtronics OLCT 80 Fixed Gas Detector

Bulk Orders

Features

- Detectors-Transmitters for Flammable, Toxic Gases and Oxygen

- Non-intrusive operation via intrinsically safe infrared remote control

- Remote versions available XP, IS

- Integrated relays

- Direct link, 4-20 mA, loop and isolated sensor mode

Unique advantages providing the solution you need

Design advantages

Pre-calibrated sensors for detection of:

- combustible gases: LEL catalytic and IR

- toxic gases

- oxygen

Alarms

- 2 integrated gas alarms with relays

- 1 fault alarm with relay

Inputs

Series 80 sensors have up to 9 glands dedicated to cable wiring Design advantages:

The minimum configuration includes:

- 1 electrical input dedicated to a sensor.

- two 4-20 mA or binary inputs. This configuration allows any other sensor from the network to be recognized (e.g temperature sensor, emergency stop, flame detector, smoke detector).

Outputs

- 4/20 mA with smart signal processing

- analog signal 4-20 mA

- data signals between 0 and 4 – 20 and 25mA

The transmitted signal, between 0 and 3.2 mA and above 20 mA, can be processed to interpret and identify a wide range of trouble parameters such as: line faults, sensor faults, embedded electronics faults, ambiguity resolution, inhibition of calibration, maintenance call (initial drift or drift over time).

- RS485 (1200 bauds, 38kb Modbus ASCII for MX 62).

The RS485 link gives access to :

– sensor measurement

– status and default

– internal relay management

Relays

The relays are 2A / 250 VAC type with potential free SPDT contacts.

Two types of relays:

- 2 gas alarm relays or supplementary inputs

- 1 fault relay

The relays are actuated either

- directly by the sensor electronics or supplementary

inputs, or - from the MX62 central unit or the control system to which the sensor is connected.

The relays can be

- in safety mode or not,

- triggered on increasing or decreasing alarms,

- manually* or automatically acknowledged.

- * By remote control, by pressing an external pushbutton connected to the dedicated binary input, by acknowledging on the MX 62 unit or the control system to which the sensor is connected.

Alarms

- 2 integrated gas alarms with relays

- 1 fault alarm with relay

Technical advantages

Stand-alone central unit

For relay control, the OLCT 80 can operate as a standalone unit: an indisputable advantage in a classified explosion risk zone.

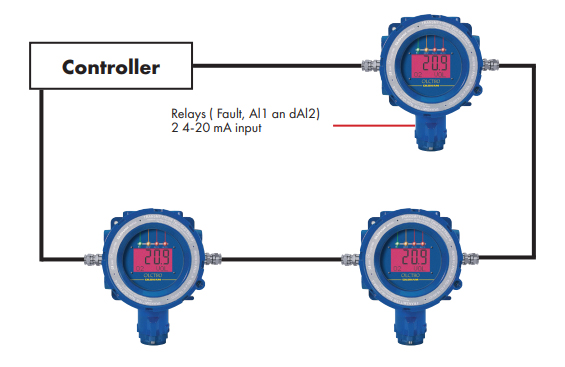

Flexibility of connection modes

OLCT 80 sensors can be connected either:

- in loop (opto-isolated – up to 16 sensors),

- 4-20 mA,

- under direct power and operate as a central unit.

Operation traceability

The operator can check records locally for the most recent time-date stamped events.

Communication

Remote dialogue with the sensor using IR remote control.

Measurement power supply redundancy

Independent ports allow a redundant connection to the measurement unit.

Low power requirements

The leading edge technology used in the OLCT80 transmitter makes it very energy efficient. This major advantage means that more sensors can be connected, with smaller wire cross-sections and over greater distances.

Logistic advantages

Loop arrangement

The transmitter is perfectly adapted to mounting and connection to the digital fieldbus loop of the MX 62 unit. Supporting 1 to 3 digital addresses:

- the sensor block (detection element),

- the two 4-20 mA auxiliary inputs.

Certification

The OLCT80 Series is certified to the specifications required by standards EN 50054, 45544 and 50104 (environmental standards, explosive and toxic gases and oxygen) and to the specifications of standards EN 50270, EN 6052 (electromagnetic compatibility, ingress protection).

OLCT 80 uses digital logic and software technologies.

The sensors are protected and in compliance with the specifications of standard EN 51271:

- analog and digital values track each other

- homogeneity of digital resolution and response time with the specifications required

- internal self-diagnostics

Configuration Options

|

|

Stand Alone Version |

Standard Version |

Stand Alone Version |

|

Specifications

| Type | Transmitter-sensor |

| Detected gases | Explosive, toxic and oxygen |

| Detection principles | Catalytic, Electrochemical, IR, Semiconductor |

| Sensor block | Pre-calibrated |

| Device | Aluminium enclosure and stainless steel 316Lfor sensor housing |

| Visualisation | 4-digit LCD display for measurement and one alphanumeric line for texts, Pictograms – backlighting 4 indicator lamps : one green : “OperationOK”, one yellow : “Fault”, red : “Alarm 1” and “Alarm 2” |

| Power supply | From 16 to 28 VDC at transmitter entry |

| Maximum power | with digital link – 0.2 W (electrochemical cell) – 1.3 W ( catalytic / SM ) with I output at 25 mA – 0.9 W (electrochemical cell) – 2 W ( catalytic / SM ) with I output at 25 mA and relays activated – 2.4 W (electrochemical cell) – 3.5 W ( catalytic / SM ) |

| Power supply to sensor terminals |

Two independent inputs : 16 to 28 VDC (catalytic / IR / SM cells) 12 to 28 VDC (electrochemical cell) |

| Inputs | Two analog inputs 4-20 mA (load resistance 120 Ω, can be used as binary) |

Signal outputs

| Logic (relay contacts) | Relay |

| Analog | Standardised 4-20 mA output |

| Digital | Two independent opto-isolated RS 485 ports |

| Signal faults | I < 0.5 mA |

| Alarms | 2 programmable thresholds per channel |

Relays

| Type | SPDT |

| Number | 3 |

| Contact | RCT changer-over |

| Breaking capacity | 2A / 250 VAC / 30 VDC |

| Wiring / connection | Basic version, 6 inputs : 4 M20 and 2 M25 On request : 3 additional, 2 M20 and 1 M25 |

| Load resistance on the 4-20 mA |

500 Ω |

| Loop resistance | Under central unit 21 VDC: 128 ohms ( electrochemical cell ) – 32 Ω ( catalytic / SM ) – 16 Ω (IR) |

| Protection number | IP 66 |

| Operating temperatures | – 20 °C to + 60 °C ( electronics, see table for detection cells ) |

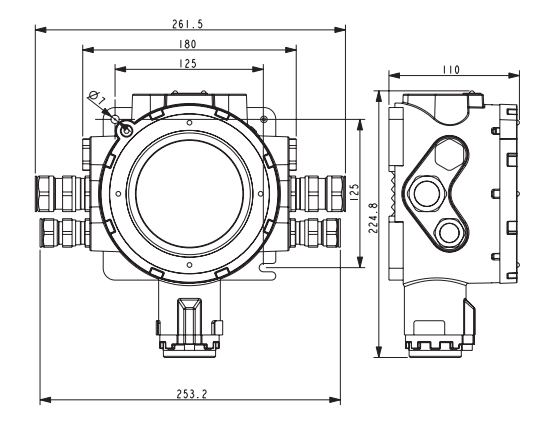

| Dimensions | See drawings |

| Weight | OLCT 80 : 3,5 kg, OLCT80 version IR : 5,3 kg |

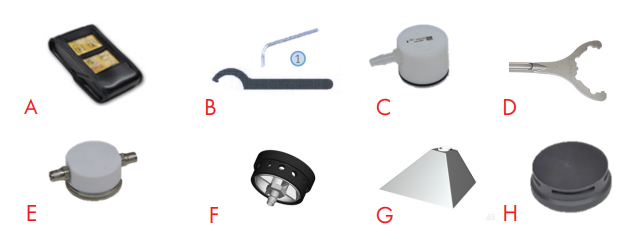

Accessories

A Infrared remote control

B Tool kit

C Bypass adapter

D Cover key

E Calibration cup

F Remote gas introduction device

G Gas collector

H Splash guard

Homologations

| Certification Atex | |

| OLCT 80 d | OLCT 80 id |

| ATEX II 2GD | ATEX II 2GD |

| Ex d IIC T6…T5 Gb | Ex d ia IIC T4 Gb |

| Ex tb IIIC T85°C…T100°C Db | Ex tb ia IIIC T135°C Db |

| INERIS 03ATEX0240X | INERIS 03ATEX0240X |

| Chine | |

| OLCT 80 d | OLCT 80 id |

| GYJ17.1201X – Ex d IIC T6/T5 Gb | GYJ17.1202X – Ex d ia IIC T4 Gb |

| Electromagnetic compatibility | |

| Complies with EN 50270 | |

![xr-series-desiccant-breathers[1]](https://www.pe-energy.com/wp-content/uploads/2019/07/xr-series-desiccant-breathers1.jpg)

![ShopTekST1500TankMount_2828557d-c638-4277-a593-2ee5ea1d9cb5[1]](https://www.pe-energy.com/wp-content/uploads/2024/08/ShopTekST1500TankMount_2828557d-c638-4277-a593-2ee5ea1d9cb51.png)

Reviews

There are no reviews yet.