Modernize your Lubricant Storage & Handling Practices

OILSAFE’s best practice, lubrication reliability solutions contribute to 5S, LEAN and TPM improvement initiatives, and assist with addressing OSHA Right-to-Know and other workplace safety and environmental compliance issues. Our innovative bulk storage & handling systems ensure the 5Rs of lubrication (Right Product, Right Time, Right Place, Right Attitude, Right Amount) are satisfied between the lube room and the point of application.

Traditional Method: Filthy, Disorganized, Unsafe, Wasteful and DESTRUCTIVE

Modern Method: Clean, Organized, Safe, Efficient, and RELIABLE

Storage System Overview

Perfect for any workplace looking to instantly establish best practices by quickly ridding itself of antiquated bulk oil storage equipment and processes. OILSAFE Bulk Storage Systems will enable you to take immediate control over your lubrication workflow process and get your lubricant storage areas and practices clean, efficient and compliant.

Simply choose one of our standard or combined models and configure it to meet your specific workplace requirements.

Features & Benefits

Clean, Safe and Professional storage and handling of bulk lubricants restores pride in the craft and drives workplace organization and efficiency

Choice of 4 Aluminum Tank sizes; (30, 65, 120 and 240 gallons)

Scalable and Configurable – scale system to accommodate the number of

lubricants required for storage and dispensing

Choice of 10 Tank Colors & Custom Identification Labeling – use colors

and labels as part of a lubricant identification convention to ensure the right lubricant

goes into the right transfer container and the right machine

Spill Control – all systems come standard with integrated spill pans for SPCC

compliance and overall environmental protection

Fire Safety – includes MSHA accepted 811HT rated flame resistant fire suppression

hoses as standard with auto-shut off tank isolation valves

Filtration – all systems come with fluid filtration capability with a choice of micron

ratings and also desiccant air breathers

Accommodate lubricants up to ISO 680

All systems ship in fully assembled pods – for efficient freight and rapid on-site installation

Transport – all systems have integrated spill transport pallets for easy forklift and

hand truck access for freight and workplace mobility

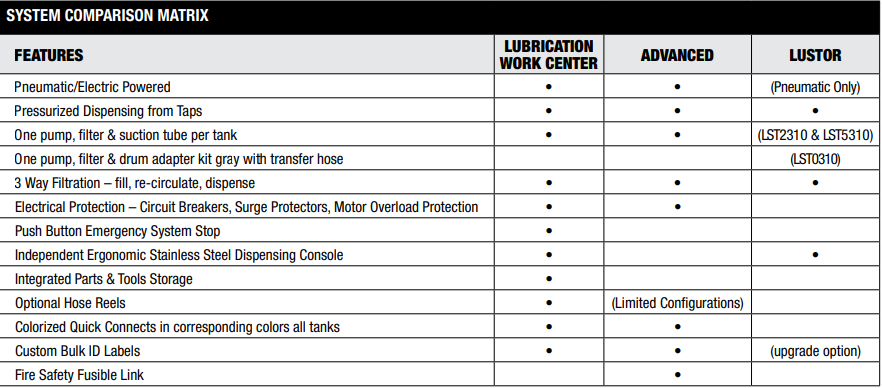

System Types & Features

The OILSAFE Storage & Handling Systems can be configured or customized to suit your application and budget

Lubrication Work Center

Advanced Bulk System

Lustor Lubrication Storage Systems

Lubrication Work Center & Advanced Bulk System Highlights

GENERAL FEATURES

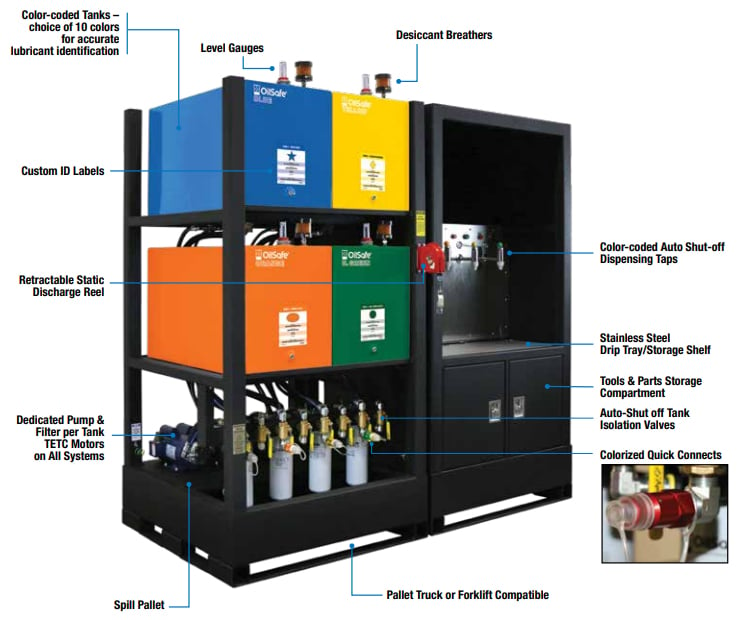

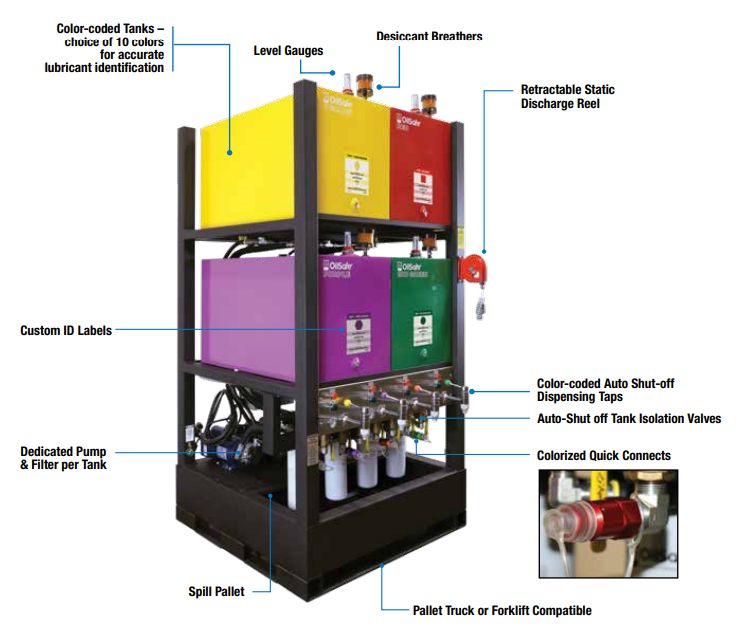

- Top Mounted Level Gauges – easy and safe viewing of tank fill level

- Retractable Cable Reel Grounding Kit & System Earth Lugs – to mitigate static-electricity build up

- Suitable for storing machinery lubricating oils and glycol based coolants

- Power – systems come standard with 110V single phase TEFC motors and can be configured for other power supplies as required. Air pneumatic option available. (240V, 50/60 Hz, Pneumatic)

TANKS

Mix and match different tanks to meet your lubricant volume and identification requirements.

- Color-coded – choice of 10 colors for accurate lubricant identification

- 4 Standard Tank Sizes – 30, 65, 120 & 240 gallons

- Heavy Duty Construction – aluminum for long life; TGIC polyester powder coated for additional durability

- Identification – systems come standard with color-coded generic labels

FLUID CLEANLINESS & CONTAMINATION CONTROL

Minimize lubricant contamination with:

- Desiccant Breather – dedicated breather for each tank ensures cleanliness by removing airborne contaminants and moisture build up

- In-line Filtration – 3 way in-line filtration – filter every time you move the fluid – fill, recirculate & dispense

- Dispense – clean oil from color-coded auto shut-off dispensing taps to transfer containers with minimal spills

- Filling

COMPLIANCE

- Fire Safety – all systems come standard with MSHA accepted 811HT rated hosing and include auto-shut off tank isolation valves for superior spill protection in the event of fire

- OSHA – Right to Know – color-coded and labeled tanks and taps ensure accurate fluid identification and handling

- EPA – SPCC – systems come standard with integrated spill containment transport pallets for EPA SPCC compliance

- Electrical Protection – Lubrication Work Centers come with circuit breakers, surge protectors, motor overload protection, grounding kit & emergency shutdown for enhanced asset and personal protection

SPILL CONTROL

Multi-Tier Spill Control

- Spill Pallets – integrated spill pallets ensure compliance with EPA – SPCC legislation

- Drip Trays – removable drip trays collect accidental drips and spills that may occur when dispensing into transfer containers. Made of stainless steel for durable long life and ease of cleaning

System Type Detail & Models

Lubrication Work Center

The OILSAFE Lubrication Work Center is a best practice solution for storage and dispensing of lubricating oils and glycol based coolants in industrial facilities. An instant Lube Room, this premium configuration incorporates best-in-class features.

| SPECIFICATIONS | |

| SPCC Spill Containment | Yes |

| Pre-assembled | Yes |

| Taps | Pressurized |

| Pumps/ Filter Set | 1 per Tank |

| 3-Way Filtration | Yes |

| Electrical Protection | Yes |

| Dispensing Console | Yes |

| High Viscosity Pumps | Yes (standard) |

| Fire Safety | Yes (standard) |

| Hose Reels | Optional |

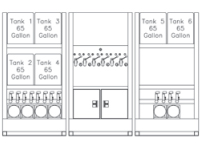

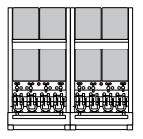

Models – Lubrication Work Centers

STANDARD MODELS

PART # : 11W0400

SIZE:

4 x 65 Gallon

92″(w) x 61″(d) x 88″(h)

PART # : 11W4200

SIZE:

2 x 65 Gallon x 4 x 30 Gallon

92″(w) x 61″(d) x 88″(h)

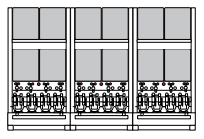

PART # : 12W0600

SIZE:

6 x 65 Gallon

138″(w) x 46″(d) x 88″(h)

PART # : 12W0420

SIZE:

4 x 65 Gallon x 2 x 120 Gallon

138″(w) x 46″(d) x 88″(h)

PART # : 12W0040

SIZE:

4 x 120 Gallon

138″(w) x 46″(d) x 88″(h)

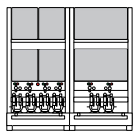

PART # : 13W0060

SIZE:

6 x 120 Gallon

184″(w) x 46″(d) x 88″(h)

PART # : 12W0040

SIZE:

4 x 120 Gallon x 1 x 240 Gallon

184″(w) x 46″(d) x 88″(h)

| INCLUDED | UPGRADE OPTIONS |

| Custom ID Labels | Overfill Alarm |

| Fire Safety Upgrade | Additional Storage Cabinet |

| Colorized Quick Connects | Suction Wand Storage |

| Hose Reel |

System Type Detail & Models – Advanced Bulk System

| SPECIFICATIONS | |

| SPCC Spill Containment | Yes |

| Pre-assembled | Yes |

| Taps | Pressurized |

| Pumps/ Filter Set | 1 per Tank |

| 3-Way Filtration | Yes |

| Electrical Protection | Yes |

| Dispensing Console | No |

| High Viscosity Pumps | Yes (standard) |

| Fire Safety | Yes (standard) |

| Hose Reels | Optional – Limited Configurations |

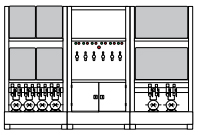

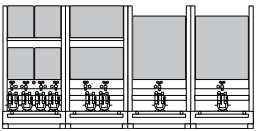

Models – Advanced Bulk Systems

STANDARD MODELS

PART # : 1A0400

SIZE:

4 x 65 Gallon

46″(w) x 61″(d) x 88″(h)

PART # : 1A0020

SIZE:

2 x 120 Gallon

46″(w) x 61″(d) x 88″(h)

PART # : 1A0001

SIZE:

1 x 240 Gallon

46″(w) x 61″(d) x 88″(h)

PART # : 1A4000

SIZE:

4 x 30 Gallon

46″(w) x 61″(d) x 88″(h)

COMBINED MODELS

PART # : 2A0800

SIZE:

8 x 65 Gallon

92″(w) x 61″(d) x 88″(h)

PART # : 3A0C00

SIZE:

12 x 65 Gallon

138″(w) x 61″(d) x 88″(h)

PART # : 1A0001

SIZE:

4 x 65 Gallon x 2 x 120 Gallon

92″(w) x 61″(d) x 88″(h)

PART # : 4A0422

SIZE:

4 x 65 Gallon x 2 x 120 Gallon x 2 x 240 Gallon

184″(w) x 61″(d) x 88″(h)

PART # : 2A0040

SIZE:

4 x 120 Gallon

92″(w) x 61″(d) x 88″(h)

PART # : 3A0060

SIZE:

6 x 120 Gallon

138″(w) x 61″(d) x 88″(h)

| INCLUDED | UPGRADE OPTIONS |

| Custom ID Labels | Overfill Alarm |

| Fire Safety Upgrade | Additional Storage Cabinet |

| Colorized Quick Connects | Suction Wand Storage |

| Hose Reel |

System Upgrade Options & Accessories

PART # 890151

Replaces bottom drawer with 76 gal spill pan.

BULK STORAGE CABINET

PART # 890150

The OILSAFE Bulk Storage Cabinet is designed to provide large capacity storage for lubrication tools and parts. The cabinet functions as either a standalone solution, or as a compliment to your OILSAFE Bulk Lubricant Storage System.

A rugged, workshop-ready solution, the OILSAFE Bulk Storage Cabinet enables immediate organization, storage and protection in one location for all of your lubrication reliability tools and shop floor products.

Features

- Workplace Organization (5S)

- Cabinet Dimensions:

45″ (w) x 45″ (d) x 88″ (h) - Four Big Deep Shelves – for bulk storage of containers, sorbents, grease guns, filters, oil analysis equipment and other fluid handling shop equipment

- Six Large Smooth Glide Drawers – with removable parts trays for storage of fittings, tools, labels and parts

- Removable Plastic Parts Bins easily clip on and off internal racks to increase storage capacity and speed for small parts selection

- All Welded, High Quality Powder Coated Cabinet used as a standalone unit or can be easily adjoined with any OILSAFE Bulk Storage System

- Ships Fully Assembled and Ready-To-Use!

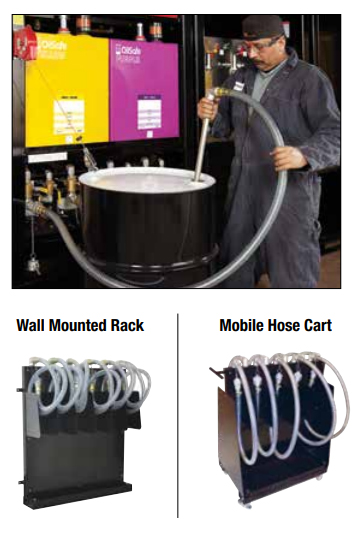

SUCTION HOSE STORAGE

After emptying drums, totes or pails, the suction hoses for the Advanced Systems and Lubrication Work Centers can be stored in the Mobile Hose Carts, on Wall Mounted Racks or if space permits on the side of your system with a Frame Mount Rack.

| SUCTION HOSE STORAGE | |

| OPTIONS | PART # |

| Mobile Suction Hose Drain Cart – 4 Hose | 895004 |

| Mobile Suction Hose Drain Cart – 6 Hose | 895006 |

| Mobile Suction Hose Drain Cart – 8 Hose | 895008 |

| Mobile Suction Hose Drain Cart – 10 Hose | 895010 |

| Mobile Suction Hose Drain Cart – 12 Hose | 895012 |

| Wall Mount Suction Hose Rack – 4 Hose | 895104 |

| Wall Mount Suction Hose Rack – 6 Hose | 895106 |

| Wall Mount Suction Hose Rack – 8 Hose | 895108 |

| Frame Mount Suction Hose Rack – 4 Hose | 895204 |

| Frame Mount Suction Hose Rack – 6 Hose | 895206 |

| Frame Mount Suction Hose Rack – 8 Hose | 895208 |

TANK OVERFILL ALARMS

Direct Mount Tank Overfill Alarms fit easily to Tank Level Gauges and can be supplied with your system or retrofitted to an existing OILSAFE Bulk Storage System.

- Audible and Flashing Light

- Can be reset even while in alarm mode

- Powered by a 9 volt Lithium Battery (supplied with battery)

- Audible Alarm 110 DB – will get your attention

- Test Switch allows you to test the battery before each use

| OPTIONS | PART # |

| Direct Mount Overfill Alarm (Audible & Flashing Light) | 897102 |

BULK SYSTEM FILTERS

β2000 Micro Glass anti-static filters are a premium filter that provides maximum dirt-holding capacity, and superior particle capture over paper filters.

Efficient operation with minimum pressure drop and high flow rate.

| 14.2″ FILTER | PART # |

| 14.2″ Filter Element β2000 – 4µ | 469962 |

| 14.2″ Filter Element β2000 – 7µ | 469964 |

| 14.2″ Filter Element β2000 – 25µ | 469966 |

| 14.2″ Water Removal Filter Element β2000 – 20µ | 469968 |

Z-134 DESICCANT BREATHER – 3.25″ x 3.25″

One case (12) desiccant breathers.

Replace breather when orange gel turns green.

| OPTIONS | PART # |

| Desiccant Breather – 3.25″ x 3.25″ | 095Z134 |

HOSE REELS

PART # 8Z0225 – 25 ft Reel

Retractable Hose Reels with trigger operated dispensing nozzles. A 3/4″ diameter hose in 25′ lengths allows dispensing to lubricant carts or other large containers.

Available with Lubrication Work Centers and limited Advanced Bulk System Configurations.

SPILL CONTAINMENT KIT

Increase Spill System Containment to be SPCC Compliant

| SPILL CONTAINMENT CONNECTOR KIT | PART # |

| 2 – Frame Connector Kit | 821352 |

| 3 – Frame Connector Kit | 821353 |

| 4 – Frame Connector Kit | 821354 |

| 5 – Frame Connector Kit | 821355 |

| 6 – Frame Connector Kit | 821356 |

DIGITAL METERING GUN

PART # 821251

Additional Storage & Bulk Handling Systems

LUSTOR™ LUBRICATION STORAGE SYSTEMS

Lustor systems deliver the storage and dispensing benefits you trust, in cost-effective, compact and expandable units. Designed to protect every liter of oil from on-site environmental conditions, Lustor systems combine proper storage, filtration and identification to create an efficient and organized, workflow. This, in turn, ensures that your lubricants remain dry and contaminant-free before they enter your equipment. Specially designed for individualized and expandable lube rooms. (For constricted space, 130 Gallon (500 Liter) Systems are stackable.)

Three different system configurations are offered to fit your application needs and requirements, these are:

Optional Upgrades/Add-ons:

- Custom Fluid ID Label – Part #PA22008LU

- 3 um Filters – LSTF3

- 20 um Filters – LSTF20

- Pneumatic 5:1 Pump – LSTPUMP5

- Lustor Spill Containment – LSTSCP

- Colorized Quick Connects

- IBC Spill Pallet

| SYSTEM CONFIGURATIONS | PART # |

| Wall Mount (no reservoir) for use with drum or tote | LST0310 |

| 65 Gallon (250 Liter) | LST2310 |

| 130 Gallon (500 Liter) | LST5310 |

SATELLITE LUBE ROOM

When your lubricants are subject to remote or extreme conditions and interior space is limited, OilSafe’s Satellite Lube Room offers a stand-alone system with placement flexibility and state of the art features. This convenient storage protects the lubricants quality and lifespan by reducing handling errors and controlling its environment. Add a Lubrication Work Center, Tote Dispensing Rack, Portable Filtration Cart and more to complete your room.

| SKID SIZE | PART # |

| Satellite Lube Room 20’ Container – Basic | 894820 |

| Satellite Lube Room 40’ Container – Basic | 894840 |

FILTRATION UNITS

Extend the life of your industrial oils, saving you time and money. They maintain purity from storage to application and eliminate cross-contamination with colorcoded/error-proof, flat face, zero-leak quick connects. Discover the cleanest and safest filtration systems on the market with three layers of spill containment to include a removable primary containment vessel, preventing spills and waste. Available in portable and stationary configurations.

| SKID SIZE | PART # |

| PRO – Wall Mount Stationary Filtration Unit | 957700 – PRO |

| BASIC – Wall Mount Stationary Filtration Unit | 957700 – BASIC |

| PRO – Portable Filtration Cart | 957780 – PRO |

| BASIC – Portable Filtration Cart | 957780 – BASIC |

55 GALLON DRUM WORK STATION

The OILSAFE 55 Gallon Drum Work Station delivers best practice contamination control for 55 Gallon Drums in a modular, ergonomic and space efficient form:

- Positive displacement Gear Pump (3-5GPM) with internal bypass

- 2-way filtration (discharge and re-circulate “kidney-loop”)

- Comes standard with 7µ, β2000 Spin on filter (4µ and 25µ also available)

- Desiccant Air Breather for Drum ventilation integrity

- Stainless Steel Dispensing Console with drip pan

- Electronic Stop/Start buttons

- Dedicated Stainless/PVC Suction Spear/Hose for Drum

- Hose Assembly with quick connects

- Delivered pre-assembled and ready-to-use

- Size: 14″(w) x 24″(d) x 65″(h)

- Drum can be placed on any standard Drum Deck/Spill Pallet for SPCC Spill Compliance if required

| MOTOR | VISCOSITY RATING | PART # |

| TEFC 110V / 14A | ≤ ISO 680 | 894500 |

| TEFC 240V / 10A | ≤ ISO 680 | 894520 |

| Air | ≤ ISO 680 | OPTIONAL |

TOTE DISPENSING RACK

The OILSAFE Tote Dispensing Rack delivers best practice contamination control for common 300 Gallon Totes in a modular, ergonomic and space efficient form.

- Positive displacement Gear Pump (3-5GPM) with internal bypass

- Retractable Hose Dispensing Reel (25 feet) with Trigger Dispenser

- Comes standard with 7µ, β2000 HP Filter with DP Indicator (4µ and 25µ also available)

- Electronic Stop/Start buttons

- Rack will accommodate Totes with base dimensions less than 41″(w) x 46″(d)

- Delivered pre-assembled and ready-to-use

- Additional Spill Pans available to expand Spill Pan capacity if SPCC Compliance is required

| MOTOR | VISCOSITY RATING | PART # |

| TEFC 110V / 14A | ≤ ISO 680 | 894500 |

| TEFC 240V / 10A | ≤ ISO 680 | 894520 |

| Air | ≤ ISO 680 | OPTIONAL |

NOTE: Tote is for illustration purposes only and not included.

USED OIL SKIDS

Provide a collection point for used oils. Each system is housed in a spill containment pallet and includes:

- 1/2” male quick connect for transferring the oils into the tank

- funnel for pouring oils in and draining out filter elements

- 4 leveling feet with forklift & pallet jack accessibility

- Identifiable white tank with a level indicator and 1-1/2” camlock access for bulk truck servicing

| SKID SIZE | PART # |

| 120 gallon Used Oil Skid | 894400 |

| 240 gallon Used Oil Skid | 894401 |

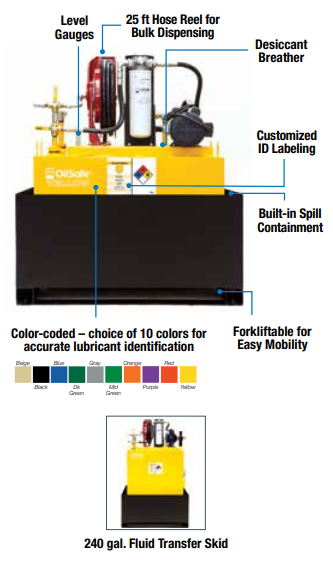

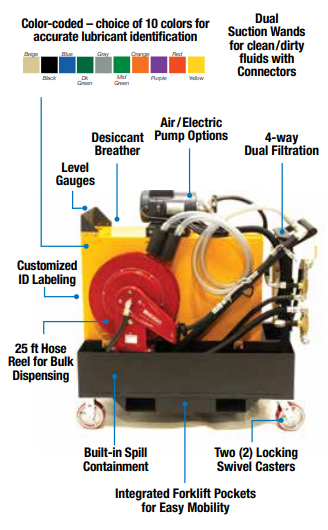

BULK FLUID TRANSFER SKIDS

Mobilize your fluids by transferring them safely utilizing an OilSafe Transfer Skid.

- 4-way filtration (fill, dispense, kidney loop & offline filtration capable

- Available in two tank sizes (120 gal and 240 gal)

- Built-in spill containment

- Integrated fork lift pockets provides easy and safe mobility via lift truck or pallet jack

- Pneumatic or Electric Pump options

- Standard 25µ Beta 2000 Spin-on-Filter for filling and dispensing

- 25-ft Fluid Hose Reel

- MSHA accepted 811HT rated flame resistant Fire Suppression Hose Assembly

- Desiccant Air Breather ensures cleanliness by removing airborne contaminants and moisture build up

- Delivered pre-assembled and ready-to-use

- Available in OilSafe’s 10 standard colors, and customized labeling for best in class fluid identification

| PART # | PRODUCT DESCRIPTION |

| 894700 | 120 gal Fluid Transfer Skid |

| 894701 | 240 gal Fluid Transfer Skid |

ADVANCED FLUID HANDLING CART

Maximize your equipment functionality with OilSafe’s Advanced Fluid Handling Cart.

- Maximum functionality

- 4-way Dual Filtration (4µ, 7µ, 25µ Beta 2000 filters available)

- Quick connects provide clean, secure connections

- 25-ft Hose Reel with high flow Dispensing Gun (Metering Gun upgrade available)

- Built-in spill containment

- Integrated forklift pockets for safe and quick mobility

- Air or Electric pump options available

- Available in OilSafe’s 10 standard colors, and customized labeling for best in class fluid identification

| PART # | PRODUCT DESCRIPTION |

| 894765 | 65 gal Advanced Fluid Handling Cart |

BREATHER ADAPTERS

Adapter Kits are available in dark gray and configured with Colorized Quick Connects* and are available in 10 OilSafe colors or silver, no Quick Connects or Iso-b Quick Connects. Adapter Kits allow breathers to be installed on any storage tank, drum, hydraulic fluid tank, reservoir or gearbox.

DRUM ADAPTER KIT

There’s never been a cleaner, more effective way to store, filter and pump lubricants from a drum. The unique design ensures all fluid handling is managed through dedicated adapters.

HYDRAULIC RESERVOIR ADAPTER KIT

The aluminum adapters have quick connects in two sizes for pumping oil in and out, allowing the system to remain closed to the environment at all times.

GEARBOX ADAPTER KIT

Oil can be pumped in or out without opening the gearbox to atmosphere. Offline filtration, oil changes and sampling can be handled through the adapter.

DOMED FLANGE ADAPTER

PART # 095A114DG

Domed Flange Adapters provide a low profile yet rugged way to mount a 1” NPT desiccant breather to a hydraulic reservoir.

Adapter Kit Part # Configuration:

Adapter Styles

Drum Adapter = 960

Hydraulic Reservoir Adapter = 961

Gearbox Adapter = 962

+ Quick Connect Size

(Only for Gearbox Adapter – 962)

1 = 1″

12 = 1/2″

34 = 3/4″

+ Quick Connect Color

BG = Beige

BK = Black

BL = Blue

DG = Dark Green

GY = Grey

MG = Mid Green

OR = Orange

PL = Purple

RD = Red

SL = Silver

YL = Yellow

ISO = No Color (iso-b)

NQ = No Connect

+ Quick Connect Type

(Do not add if NQ picked for Quick Connect Color)

M = Male

MF = Male & Female

(EXAMPLE: 960BGM – Drum Adapter, Beige, Male)

COLORIZED QUICK CONNECTS

Offer a flexible, durable and safe hose interface for use with lubrication management equipment. Manufactured from anodized aluminum, then color-coded, these connects are specially designed to eliminate cross-contamination once and for all. They are available in 10 familiar OilSafe colors* or silver to easily identify fluid contents and set the bar with an error-proof/exclusive fit. Only two terminals of the same color can fully connect making cross-contamination impossible. Our OilSafe Quick Connects keep your machinery and fluids lasting longer while maintaining a safe work environment with precise and secure connections that eliminate leaks, spills and waste.

| 1/2” MALE | 1/2” FEMALE | 3/4” MALE | 3/4” FEMALE |

| PART # | PART # | PART # | PART # |

| M8 Orange | F8 Orange | M12 Orange | F12 Orange |

| M8 MidGreen | F8 MidGreen | M12 MidGreen | F12 MidGreen |

| M8 DrkGreen | F8 DrkGreen | M12 DrkGreen | F12 DrkGreen |

| M8 Blue | F8 Blue | M12 Blue | F12 Blue |

| M8 Purple | F8 Purple | M12 Purple | F12 Purple |

| M8 Red | F8 Red | M12 Red | F12 Red |

| M8 Beige | F8 Beige | M12 Beige | F12 Beige |

| M8 Black | F8 Black | M12 Black | F12 Black |

| M8 Gray | F8 Gray | M12 Gray | F12 Gray |

| M8 Yellow | F8 Yellow | M12 Yellow | F12 Yellow |

| M8 Silver | F8 Silver | M12 Silver | F12 Silver |

*Colorized quick connects have been inspected to ensure anodized colors are within OilSafe color spectrum scope. Color and shade can vary on anodized components, this will not impact performance of product.